Product

Compo S-Series

S-90ET

Full-universal type of COMPO S-90ET works well input objects with wide-rang whatever high and low gravity materials.

Main Specifications

| Model | S-90ET | |

|---|---|---|

| Fermentation-tank volume | 86m³ | |

| Intake bucket volume | 1.5m³ | |

| Unit weight | 30.0t | |

| Power frequency | 50Hz | 60Hz |

| Upper blower | 2.0kw | 2.4kw |

| Lower blower | 11.0kw×2 | 9.5kw×2 |

| Hydraulic unit | 7.5kw | |

| Hopper motor | 0.2kw | |

| Intake-bucket winch motor | 2.2kw | |

| Exhaust blower | 2.2kw | |

| Heater | 5.0kw | |

| Total | 41.1kw | 38.5kw |

| Total excluding heater | 36.1kw | 33.5kw |

Typical Electoricity Usage

| Power frequency | 50Hz | 60Hz |

|---|---|---|

| Monthly (W Heater) | 24,750.0kwh/M | 22,878.0kwh/M |

| Monthly(W/O Heater) | 21,150.0kwh/M | 19,780.0kwh/M |

*Heater is necessary when intake air temperature is below 5 degree. "Lower blower of S-90ET works single or double according to the gravity of input object.

Treatment Capacity per day

| Capacity | Pig (78% water content) |

Poultry (60% water content) |

|---|---|---|

| Input object | 6.0 t | 12.0 t |

| Output product | 1.5 t | 7.2 t |

Note: Treatment capacities may vary according to season or local.

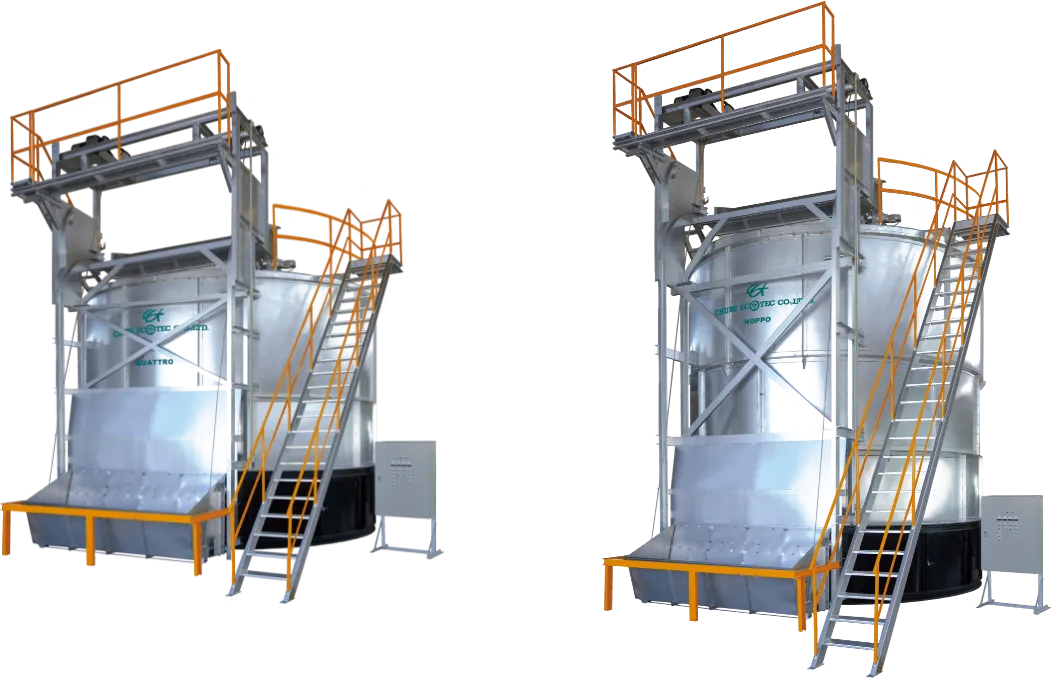

S-90ET QUATTRO & S-90ET NOPPO

New line-ups are based on S-90ET and optimized the design of high gravity for QUATTRO and low gravity for NOPPO.

Main Specifications

| Model | S-90ET QUATTRO | S-90ET NOPPO | ||

|---|---|---|---|---|

| Fermentation-tank volume | 69m³ | 102m³ | ||

| Intake bucket volume | 1.5m³ | 1.5m³ | ||

| Unit weight | 27.0t | 35.0t | ||

| Power frequency | 50Hz | 60Hz | 50Hz | 60Hz |

| Upper blower | - | - | - | - |

| Lower blower | 11.0kw×2 | 9.5kw×2 | 11.0kw×2 | 9.5kw×2 |

| Hydraulic unit | 7.5kw | 7.5kw | ||

| Hopper motor | 0.2kw | 0.2kw | ||

| Intake-bucket winch motor | 2.2kw | 2.2kw | ||

| Exhaust blower | 2.2kw | 2.2kw | ||

| Heater | 4.0kw | 4.0kw | ||

| Total | 38.1kw | 35.1kw | 38.1kw | 35.1kw |

| Total excluding heater | 34.1kw | 31.1kw | 34.1kw | 31.1kw |

Note: Power requirements of auxiliary equipment vary according to the installation method.

Typical Electoricity Usage

| Model | S-90ET QUATTRO | S-90ET NOPPO | ||

|---|---|---|---|---|

| Power frequency | 50Hz | 60Hz | 50Hz | 60Hz |

| Monthly (W Heater) | 22,590.0kwh/M | 20,430.0kwh/M | 22,590.0kwh/M | 20,430.0kwh/M |

| Monthly (W/O Heater) | 19,710.0kwh/M | 17,550.0kwh/M | 19,710.0kwh/M | 17,550.0kwh/M |

Treatment Capacity per day

| Model | S-90ET QUATTRO | S-90ET NOPPO | ||

|---|---|---|---|---|

| Capacity | Input object | Output product | Input object | Output product |

| Pig(78% water content) | 6.0 t | 1.5 t | 5.0 t | 1.3 t |

| Poultry(60% water content) | 10.6 t | 6.3 t | 13.7 t | 8.2 t |

Solution of Environment

Full-universal type of COMPO S-90 works well input objects with wide-rang whatever high and low gravity materials.

New line-ups are based on S-90 and optimized the design of high gravity for QUATTRO and low gravity for NOPPO.

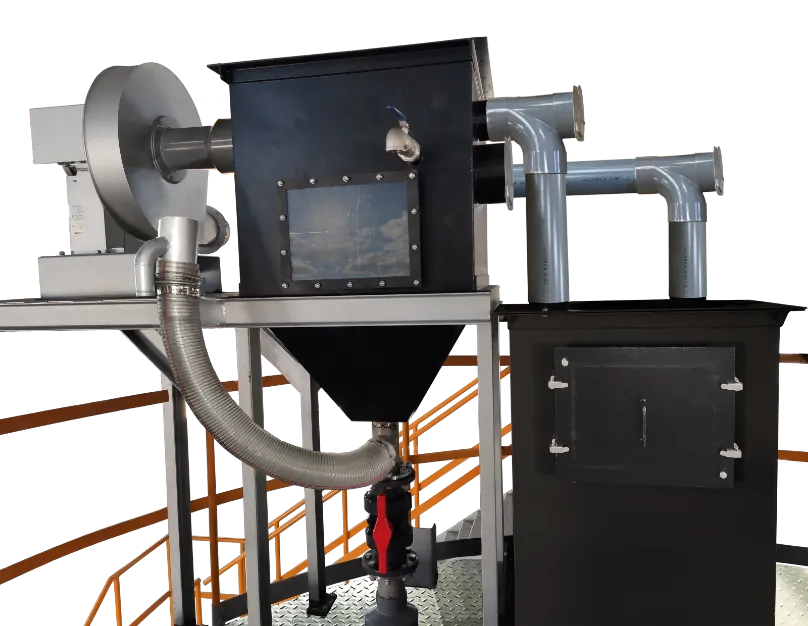

Renewed Exhaust System

- Cyclone Dust Remover

- Micro-dust canceler.

- Head space reducer.

- Heat loss protection.

- Anti-rust design.

- Semi-maintenance free.

- Venturi Water Deodorizer

- Dissolution enhancer.

- Compact design.

- Sludge dropper.

- Anti-rust design.

- Semi-maintenance free.

- Special Exhaust Blower

- Anti-rust design.

- Weather proof.

- Tough durability.

- High-efficiency motor.

- Produced by CHUBU ECOTEC made in Japan.